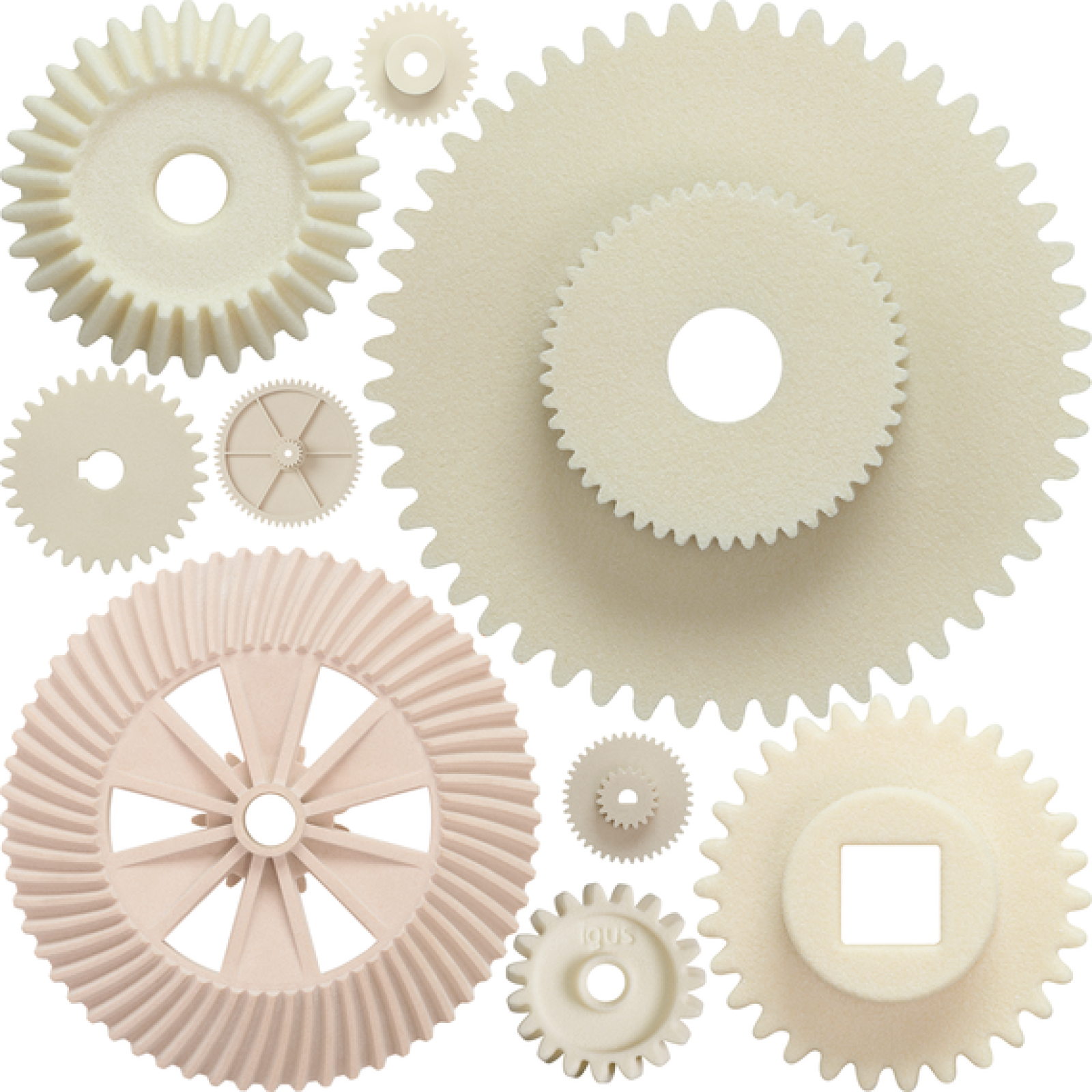

What are Plastic and Composite Gears?

Plastic and composite gears are lightweight, silent and corrosion-resistant gear types produced as an alternative to traditional metal gears. These gears, produced from polymer-based materials, are preferred especially in applications requiring low to medium loads due to their wear resistance and low friction advantages.

Areas of Use:

Automotive: Used in low torque applications such as window lifters, seat mechanisms, air duct guidance systems.

Medical Devices: Preferred in MRI and X-ray machines, biomedical devices due to their silent and non-magnetic structure.

Home Appliances: Used in coffee machines, food processors and vacuum cleaners for their light and silent operation.

Power Tools: Used in the internal mechanisms of devices such as drills and saws.

Aerospace and Defense: Used in systems requiring low weight and special durable composite materials.

Features:

Lightness: It has a much lower density compared to metal, which reduces the total weight of the system.

Low Noise and Friction: It operates quieter than metal gears and requires less lubrication.

Corrosion Resistance: It is resistant to factors such as moisture, chemicals and salt water.

Low Cost: It costs less than metal in mass production.

Electrical Insulation: Since it is not electrically conductive, it is safe in systems requiring electrical insulation.

Materials Used:

Thermoplastics:

Composite Materials: