Definition of Reducer Gears

Reducer gears are mechanical gear systems that transmit high-speed (fast) motion from motors at lower speed and high power by reducing it to the desired torque level. Gearboxes are used in many areas from industrial machinery to automotive systems and are designed to provide power transmission, torque increase and speed control.

Tasks of Reducer Gears

✔ Speed Reduction - Reduces the high speed of the motor to a controlled and desired level.

✔ Torque Boost - Generates high power at low speed, making it easier to move heavy loads.

✔ Power Transmission - Ensures the most efficient transfer of energy.

✔ Vibration and Noise Reduction - Especially helical and planetary gears offer quiet and vibration-free operation.

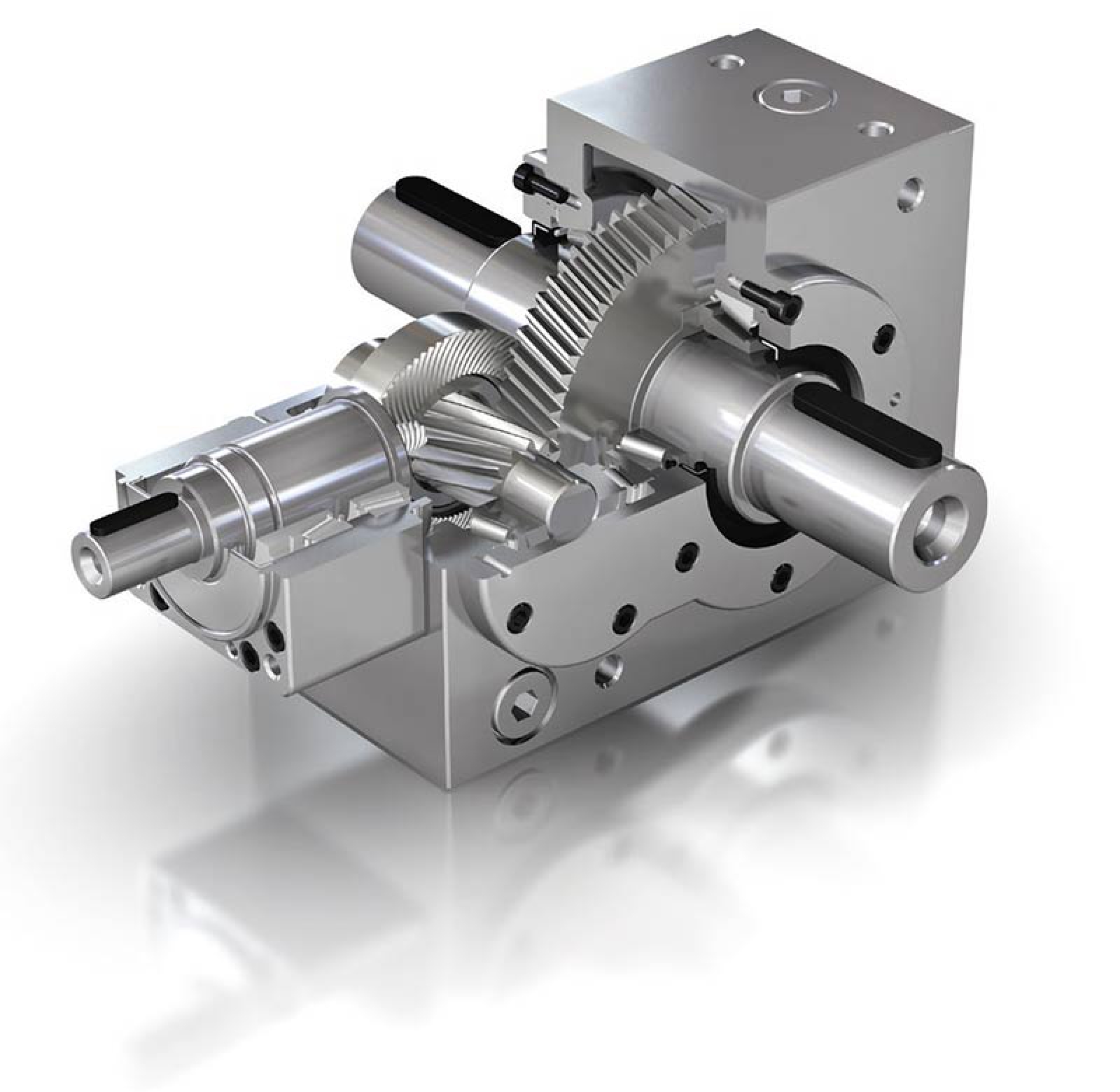

Reducer Gear Types

Spur Gears → Simple and efficient, but noisy at high speeds.

Helical Gears → Provides quieter and more efficient power transmission.

Bevel Gears → Used to change the direction of movement by 90°.

Planetary Gears → Provides high torque and precise speed control with its compact structure.

Worm Gears → Offer large speed reduction ratios and unidirectional motion locking feature.

Areas of Use of Reducer Gears

Industrial Machinery - Conveyors, cranes, press machines.

Agricultural Machinery - Hoeing machines, harvesters, tractors.

Automotive Industry - Differential and transmission systems.

Robotics and Automation -